Source: Pinterest

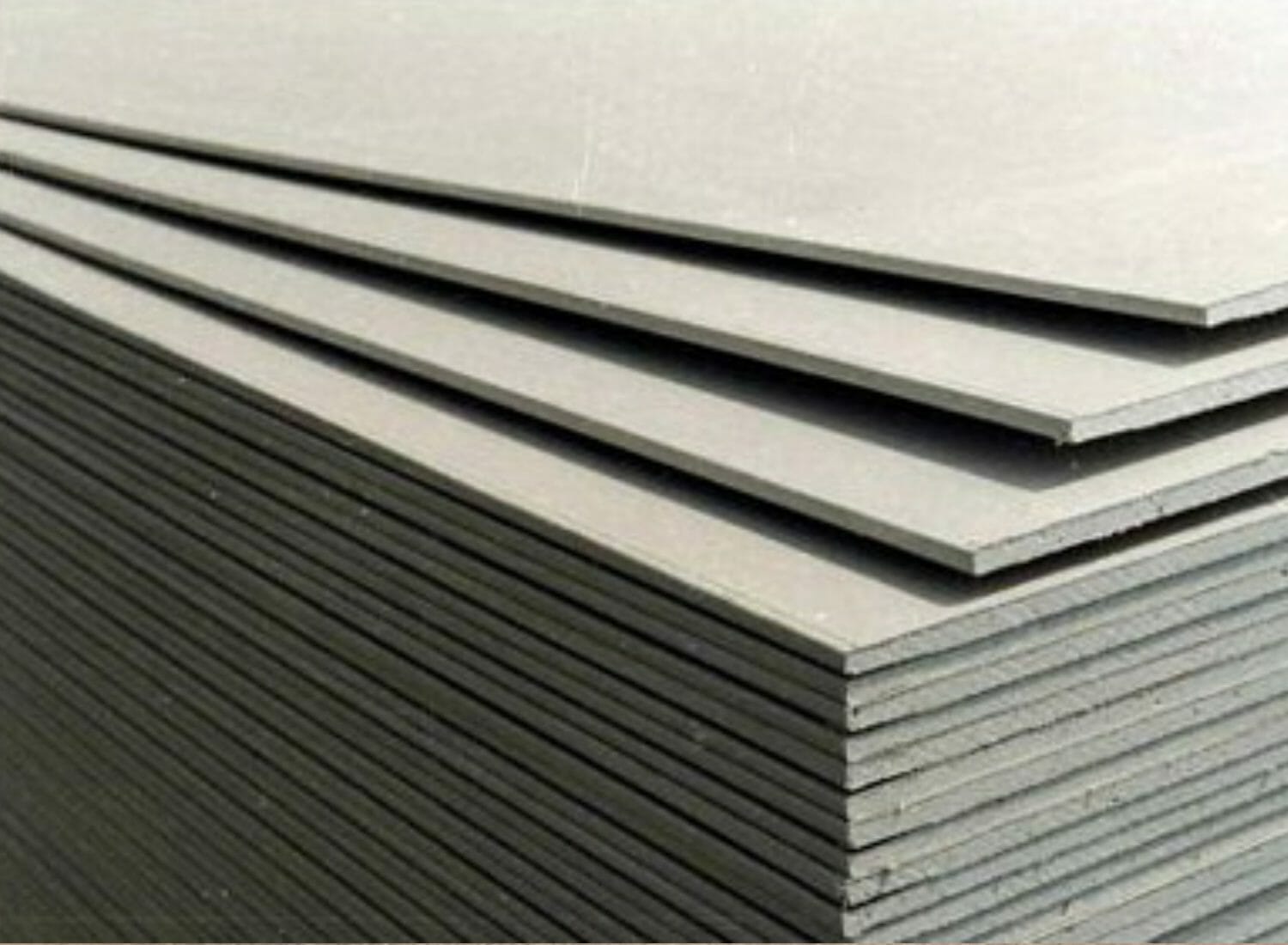

Drywall is a popular construction material used for walls and ceilings. However, many people are unaware of the history behind this ubiquitous building material, including when it was first invented.

Drywall was first invented in 1916 by a man named Augustine Sackett. He observed the use of plaster-coated wooden boards as a building material and realized that there had to be a better way to construct walls and ceilings.

Since its invention, drywall has become a staple of modern construction and can be found in homes, offices, and other buildings around the world.

Origin of drywall

Source: Pinterest

The origin of drywall can be traced back to the late 19th century, when Augustine Sackett invented a new type of board made from layers of plaster and paper. This board, which he called Sackett Board, was the precursor to modern-day drywall.

Sackett plasterboard company

In 1894, Sackett founded the Sackett Plaster Board Company to manufacture his invention. However, the company struggled to make the board on a large scale, and he eventually sold the patent to United States Gypsum Corporation (USG) in 1901.

USG refined Sackett’s invention, replacing the plaster with gypsum, a naturally occurring mineral that is abundant in the United States. This new material was lighter and stronger than plaster, making it easier to transport and install.

The first gypsum-based wallboard

Source: TheAtlantic

In 1917, USG introduced the first gypsum-based wallboard, which they called Sheetrock. The popularity of drywall grew rapidly in the early 20th century, replacing traditional plaster and lath construction methods.

By the 1950s, drywall had become the standard material for interior walls and ceilings in residential and commercial buildings.

Today, drywall is made by a lot of manufacturers and is available in a variety of sizes and thicknesses to meet the needs of different construction projects. Its popularity and versatility made it an essential component of modern construction.

Development and evolution of drywall

Source: Flickr

Drywall, also known as gypsum board, wallboard, or sheetrock, is a building material used to create walls and ceilings. It is made of gypsum plaster, which is sandwiched between two layers of paper or fiberglass matting.

The use of drywall has become widespread in modern construction due to its ease of installation, fire-resistance, and low cost.

The first gypsum board

The history of drywall can be traced back to the early 20th century when Sackett Plasterboard Company developed the first gypsum board. The board was made by sandwiching gypsum plaster between two sheets of felt paper.

The material was heavy and difficult to work with, but it was still an improvement over traditional plaster and lath construction. Over the years, drywall technology continued to evolve.

Gypsum panels

In the 1930s, gypsum panels were introduced, which were lighter and easier to handle than the earlier felt paper boards.

Gypsum lath

In the 1940s, gypsum lath was developed, which could be used to create a solid base for plaster without the need for wooden lath.

Rock lath

In the 1950s, the introduction of rock lath, a gypsum panel with a perforated surface, allowed for the use of mechanical fasteners, making installation even easier.

Drywall added with starch and plasticizer

In the 1960s, the addition of starch and plasticizer made drywall more flexible, while the use of foaming agents improved its insulation properties.

Drywall with glass fiber matting

In the 1970s, the use of glass fiber matting and buster boards further improved drywall’s strength and durability. Today, modern drywall is made with a variety of materials, including gypsum panel, fiberglass, and even recycled paper.

The use of drywall has become an integral part of modern construction, and it continues to evolve with new technologies and materials.

Drywall and the construction industry

Source: iStock

Drywall, also known as gypsum board or plasterboard, is a widely used building material in the construction industry.

It is a panel made of gypsum plaster compressed between two thick sheets of paper, and it has become the industry standard for interior walls and ceilings in residential and commercial construction.

Drywall reducing required time and labor

Drywall has revolutionized the construction industry by significantly reducing the time and labor required to finish interior walls and ceilings. It is also a more cost-effective option compared to traditional plaster finishes.

The ease of installation has made it a popular choice for both residential and commercial construction projects.

Drywall being fire-resistant

In addition to its ease of installation and cost-effectiveness, drywall is also a fire-resistant material.

The gypsum core of the drywall contains water, which is released as steam when exposed to fire, providing a protective barrier that slows down the spread of flames.

This property makes drywall a popular choice in commercial construction projects where fire safety is a top priority.

Drywall and interior design

Source: Pinterest

Drywall has become a popular choice for interior design because of its many benefits, including ease of installation, durability, and flexibility.

One of the primary advantages of drywall is its versatility.

Interior design styles

It can be used to create a wide range of interior design styles, from traditional to modern, and it can be finished in a variety of ways to achieve different looks.

For example, drywall can be painted, wallpapered, or textured to create a unique and personalized look for any room.

Ease and accessibility

Another benefit of drywall is that it is easy to install. It can be cut to fit any size or shape of room, and it can be installed quickly and efficiently by a professional.

This makes it an ideal choice for both new construction and renovation projects.

In addition to its ease of installation, drywall also offers excellent durability.

Other drywall features

It is resistant to fire, mold, and moisture, making it a safe and long-lasting choice for any interior design project.

Drywall also helps to reduce noise transmission between rooms, making it an excellent choice for creating private and peaceful spaces.

When installing drywall, it is important to pay attention to the joints and seams. Properly sealing these areas is crucial to achieving a smooth and seamless finish.

This can be done using joint compound and tape, which helps to create a strong and durable bond between the drywall panels.

Drywall in architecture and building material history

Ancient plaster

Soure: Flickr

While drywall is a relatively new building material, the use of plaster and other materials to create smooth walls and ceilings dates back to ancient civilizations.

The Greeks and Romans used a mixture of gypsum, sand, and water to create plaster walls, while the ancient Egyptians used a similar mixture of gypsum and lime.

Modern plaster

Soure: Flickr

In modern times, drywall has become a ubiquitous building material due to its ease of installation and relatively low cost.

It is made by sandwiching a layer of gypsum plaster between two layers of paper or fiberglass, creating a lightweight and durable panel that can be easily cut and installed.

Drywall is not without its drawbacks. It is susceptible to water damage and can be easily damaged by impacts or heavy loads. It also requires significant energy to manufacture and cannot be easily recycled.

Properties and advantages of drywall

Drywall, also known as gypsum board, is a widely used building material that was invented in the early 20th century. It is composed of gypsum plaster that is sandwiched between two layers of paper or fiberglass mats.

Fire resistance

Soure: Flickr

One of the major advantages of drywall is its fire resistance. Due to its composition, it is able to withstand high temperatures and can help prevent the spread of fire. In fact, it is commonly used in fire-rated assemblies.

Mold resistant

Soure: Flickr

Another advantage of drywall is its mold-resistant properties. It is made with materials that do not promote mold growth and can help prevent the growth of mold on walls.

This makes it a great choice for areas with high humidity or moisture, such as bathrooms and kitchens.

Durable

Soure: Flickr

Drywall is also known for its durability. It is able to withstand normal wear and tear and can last for many years without needing to be replaced.

In terms of efficiency, drywall is an affordable building material that is easy to install. It can be cut to fit any size or shape and can be installed quickly and efficiently. It also provides a smooth finish that is easy to paint or decorate.

Water resistant

Soure: Flickr

Additionally, it is resistant to water damage, which helps to prevent the growth of mold and other types of water damage.

Overall, drywall is a versatile and practical building material that offers a variety of advantages. Its fire-resistant, mold-resistant, and water-resistant properties make it a great choice for a wide range of applications.

Additionally, its affordability, durability, and efficiency make it a popular choice among builders and homeowners alike.

Impact of historical events on drywall use

Drywall has become a popular material for construction and renovation projects in modern times. However, its evolution and widespread use were influenced by several historical events.

Here are some of the major events that shaped the use of drywall:

World War II

Soure: Flickr

During World War II, there was a shortage of skilled labor and building materials. To address this issue, the US government encouraged the use of drywall in construction projects.

Drywall was easier to install and required less labor than traditional plaster walls. As a result, drywall became more popular and widely used in post-war construction projects.

Baby boom

The post-World War II era also saw a significant increase in population, known as the baby boom. This led to a surge in demand for housing, and drywall became an attractive option due to its ease of installation and affordability.

The use of drywall expanded rapidly during this period, and it became the preferred material for interior walls and ceilings.

Urban fires

Soure: Flickr

Large urban fires, such as the Great Chicago Fire in 1871 and the San Francisco earthquake in 1906, led to the development of fire-resistant building materials. Drywall was initially developed as a fire-resistant alternative to plaster walls.

It was made with gypsum, a naturally fire-resistant mineral, and paper facing that provided additional protection. This made drywall a popular choice for construction projects in areas prone to fires.

Civil war

Soure: Flickr

The Civil War led to a shortage of building materials, and builders had to find new ways to construct homes and buildings. One solution was to use drywall, which was easier to transport and install than traditional plaster walls.

This helped popularize drywall as a construction material.

Chinese drywall

Soure: Flickr

In the early 2000s, there was a surge in demand for drywall due to the housing boom. This led to a shortage of domestic drywall, and builders began importing drywall from China.

However, this Chinese drywall was found to contain high levels of sulfur and other chemicals that caused health problems and damage to homes. This led to a decline in the use of Chinese drywall and increased scrutiny of imported building materials.

Drywall and environmental considerations

Drywall, also known as gypsum board or plasterboard, is a widely used construction material for walls and ceilings.

The invention of drywall revolutionized the construction industry, providing a faster, cheaper, and more fire-resistant alternative to traditional plaster and lath.

But as with any construction material, there are environmental considerations to be aware of.

Gypsum dust

Soure: Flickr

One of the main environmental concerns associated with drywall is the production of gypsum dust. Gypsum is a naturally occurring mineral that is mined from the earth and processed into a fine powder to make drywall.

During the manufacturing process, gypsum dust can be released into the air, posing a potential health risk to workers and nearby residents.

To mitigate this risk, manufacturers use various dust control measures, such as water sprays and ventilation systems.

Drywall waste

Soure: Flickr

Another environmental consideration is the disposal of drywall waste. While drywall is recyclable, it is often disposed of in landfills, where it can take up valuable space and potentially release harmful gasses like hydrogen sulfide.

Some landfills have implemented special programs for drywall recycling, but these programs are not yet widespread.

Recycling

Soure: Flickr

On the other hand, drywall waste can also be repurposed for agricultural products. Some farmers use drywall as a soil amendment to improve soil structure and increase crop yields.

Drywall contains calcium and sulfur, which are essential nutrients for plant growth.

However, it is important to note that not all drywall waste is suitable for agricultural use, as it may contain contaminants like asbestos or lead.

While drywall is a versatile and widely used construction material, it is important to consider its environmental impact.

Manufacturers and construction professionals should take steps to minimize dust exposure during production and properly dispose of drywall waste. The agricultural industry may find value in repurposing drywall waste as a soil amendment.

Drywall market and sales

Source: Freepik

Drywall, also known as gypsum board or plasterboard, is a popular building material used in modern construction. It was invented in the early 20th century as a replacement for traditional plaster and lath walls.

Since then, drywall has become the standard material for interior walls and ceilings in the United States and many other countries.

United States Gypsum Company (USG)

The drywall market in the United States is dominated by a few major manufacturers, including the United States Gypsum Company (USG). USG was founded in 1902 and played a key role in the development of the drywall industry.

Today, USG is one of the largest gypsum board producers in the world, with a wide range of products and services for the construction industry.

Other companies

In addition to USG, there are many other companies that produce and sell drywall in the United States. These companies include National Gypsum, American Gypsum, CertainTeed, and Georgia-Pacific.

Gypsum Association

The Gypsum Association, a trade association representing gypsum board manufacturers in North America, provides technical information and resources to help promote the use of gypsum products.

Sales of drywall are driven by demand from the construction industry, which is influenced by factors such as population growth, economic conditions, and government policies.

According to a report by ResearchAndMarkets.com, the global market for drywall is expected to grow at a compound annual growth rate of 5.5% from 2020 to 2025.

Challenges and issues with drywall

Drywall has become a popular building material due to its cost-effectiveness and ease of installation. However, there are several challenges and issues associated with drywall that can affect its performance and durability.

Water absorption and mold growth

One of the most significant challenges with drywall is its susceptibility to water damage and mold growth. Drywall is made from gypsum, which is a porous material that can absorb water quickly.

When drywall gets wet, it can become a breeding ground for mold and other fungi, which can cause health problems for occupants and weaken the structural integrity of the building.

Hurricane Katrina

Hurricane Katrina in 2005 highlighted the issues with water damage and mold growth in drywall.

After the storm, many homes and buildings in the affected areas had to be gutted and rebuilt due to mold growth caused by water damage to drywall.

Mold resistance

To address the issue of mold growth, manufacturers have developed mold-resistant drywall. This type of drywall has a special coating that inhibits the growth of mold and other fungi.

However, mold-resistant drywall is more expensive than regular drywall and may not be necessary in all applications.

Rensselaer polytechnic institute

Researchers at Rensselaer Polytechnic Institute have developed a new type of drywall that is resistant to water damage and mold growth. This type of drywall is made from a combination of gypsum and a polymer that repels water.

This innovation has the potential to revolutionize the drywall industry and improve the durability and safety of buildings.

Gypsum mines

Drywall is made from gypsum, which is a mineral that is mined from the earth. The mining of gypsum can have environmental impacts, including the destruction of natural habitats and the contamination of water sources.

Some manufacturers have started using synthetic gypsum, which is made from waste products from coal-fired power plants, to reduce the environmental impact of drywall production.

Boston and Chicago

In recent years, Boston and Chicago have experienced issues with drywall that was imported from China.

This drywall was found to contain high levels of sulfur, which caused corrosion of metal components in buildings and health problems for occupants. The issue led to lawsuits and recalls of the affected drywall.

Overall, while drywall has many benefits, it is important to be aware of the challenges and issues associated with it.

By understanding these issues, builders and homeowners can make informed decisions about the use of drywall in their projects.

FAQ’s

When did drywall become widely used?

Drywall, also known as gypsum board, became widely used in the United States in the 1940s and 1950s. It quickly became a popular alternative to plaster and lath, as it was easier and faster to install.

What did they use before drywall?

Before the invention of drywall, builders used plaster and lath to create walls and ceilings. This involved nailing thin strips of wood, called lath, to the wall studs, and then applying several coats of plaster over the lath to create a smooth surface.

How thick was drywall in 1950?

In the 1950s, standard drywall thickness was 1/2 inch. However, thicker drywall was available for special applications, such as soundproofing or fire resistance.

Yes, drywall was still widely used in the 1960s, and continues to be the most popular wall and ceiling material in the United States today.

What are some drywall alternatives?

There are several alternatives to drywall, including wood paneling, plaster, metal panels, and cement board.

Each of these materials has its own advantages and disadvantages, and the choice of material will depend on the specific needs of the project.

Drywall itself is not toxic, but some types of drywall can emit harmful chemicals, such as formaldehyde, into the air.

It is important to use drywall that meets environmental and safety standards, and to ensure that it is properly installed and ventilated.