Drywall, often referred to as sheetrock, gypsum board, wallboard, plasterboard, custard boards, or buster boards, is constructed from gypsum. This material is scientifically recognized as Calcium Sulphate Dihydrate.

The drywall consists of two paper boards sandwiching the gypsum panel. Also, plywood, wood pulp, and asbestos-cement boards are some of the drywall materials available. Wood fiber and pulp boards are formed with wood grain and have a variety of other surface characteristics by compressing layers or particles of wood with adhesives.

Let’s know about it in detail.

Drywall: an overview

Drywall is a type of material used to build walls and ceilings. It’s also used to make a variety of design elements, such as eaves, arches, and other architectural details. It’s quick and simple to put together, quite durable, and only requires minor repairs if it breaks.

It’s a gypsum plaster sheet or panel sandwiched between thick sheets of fiberglass mats or heavy paper in the construction industry. It’s a popular choice for interior walls and ceilings.

Raw gypsum, plasticizer, finely crushed gypsum crystals, foam, ethylenediaminetetraacetic acid (EDTA), wax emulsion, and different additives are used to make gypsum plaster. To make rigid boards or panels, the solution is layered between the outside sheets and cured. Plasterboard, gypsum board, and sheetrock are all alternative terms for drywall.

Drywall is used to cover pillars to hide steel beams in office properties and is a quick and economical technique to finish thick walls over ceilings. Drywall can also be used to increase fire resistance to walls and ceilings, limiting the spread of fire and allowing people to safely evacuate in the event of a fire.

Nowadays, it is common to see the wide use of drywall. You can see it everywhere these days: in shops, in your house, in corporate offices, and so on.

What is drywall made of?

Materials

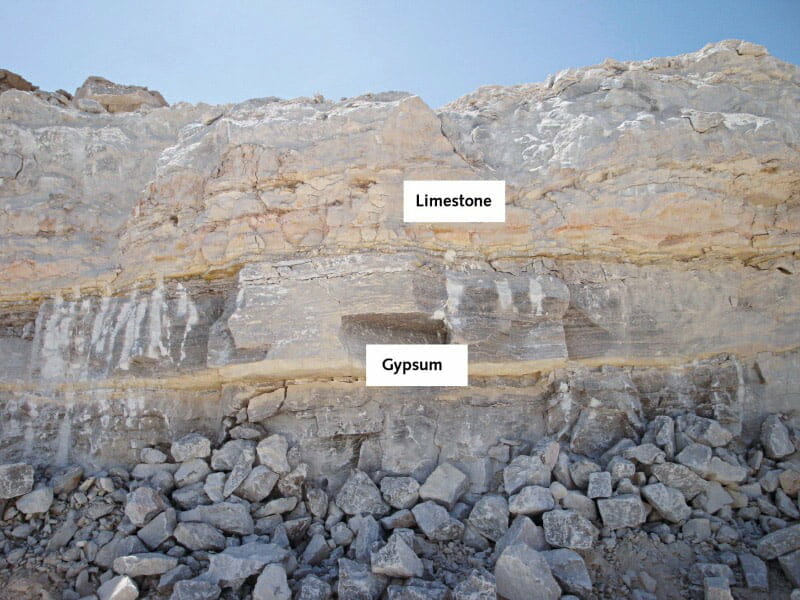

The mineral gypsum is the most important component of drywall. It’s a low-density rock that can be found in large deposits all over the world. Each gypsum (or dihydrous calcium sulfate) molecule is made up of two water (H 2 0) molecules and one calcium sulfate molecule (CaSO 4 ). The compound is 21 percent water by weight but nearly 50 percent water by volume.

The material is dry because the water in gypsum is in crystalline form.

By now, you know that gypsum is used to produce drywalls. But what is gypsum? Let’s know.

About gypsum

In North America, millions of tonnes of gypsum are mined yearly, with gypsum board being the most common product. Aside from newly mined gypsum, up to 20% of the gypsum used to create drywall can be recycled from waste generated at the factory or on building sites.

Gypsum produced as a byproduct of electric power plants’ flue-gas desulfurization process is a cost-effective and environmentally friendly raw material for producing high-quality gypsum board.

Usage of gypsum

The ancient Greeks called gypsum gypsies, and it is one of the most useful minerals known to man. It is usually white in its purest form, but impurities cause it to turn gray, brown, pink, or black. It was known as alabaster by the ancient Assyrians, who used it to create sculptures. Pulverized gypsum is now used for a wide range of purposes.

It is found in several toothpaste brands and is used as a filler in paint, cosmetics, and pharmaceuticals. While being polished, automotive window glass is fixed in a gypsum bed.

Gypsum is used as a fertilizer and soil conditioner on fields. It is used to fortify foods like bread since it is a great source of calcium. It’s even been utilized in movies to produce fake snowstorms.

Use of papers in drywall

The majority of drywall is created from two types of paper, both of which are made from recycled newspapers. When properly primed, the ivory manila face paper readily accepts most paints and other types of wall finishing treatments.

The gray back paper can be layered with aluminum foil to create a particular form of drywall that resists water vapor flow in bathrooms.

Different types of paper may be used to make specialized gypsum boards; for example, certain papers are meant to be moisture resistant to varying degrees, while another type of extremely absorbent drywall paper is designed to accept a thin coat of plaster veneer after installation.

Dangerous components in drywall

Hazardous compounds identified in drywall panels, mainly in items manufactured in China, have received a lot of recent attention.

Sulfur, for example, has been discovered in Chinese drywall but not in most drywall created in the United States.

Electrical wires and water lines have been corroded due to high sulfur levels in drywall. Strontium has been identified in both Chinese and American drywall, albeit the concentrations in Chinese products are substantially higher.

Some drywall products also contain antimicrobial chemicals to combat mold and mildew, which can be irritating to sensitive people.

Different types of drywall

Choose the correct type of drywall for the job if you want it to last a long time. There are six basic types of drywall to choose from, each with its own set of advantages.

Regular drywall

On one side, regular drywall is white, and on the other, it is brown. It is also most likely the most cost-effective drywall variety, with thicknesses ranging from 3/8 inch to one inch. This is the most prevalent form, with four by eight-foot panels being the most frequent size.

Paperless drywall

This type of drywall has almost replaced traditional drywall. Instead of paper, this form of drywall is wrapped with fiberglass, which protects it from rot, and provides mold and mildew resistance.

Although the quality of paperless drywall is slightly higher than that of conventional drywall, some building professionals find it easier to cut.

Because paperless drywall includes some subtle textures, a joint compound will be needed to obtain a smooth, clean finish drywall level.

Plasterboard

Plasterboard, also known as the blue board, is similar to lath in lath and plaster walls in that it serves as a substrate for plaster applications. A thin coat or coats of plaster must be applied to the whole surface of the plasterboard.

Because the face paper absorbs moisture, the plaster finish layer adheres to the drywall better. It’s used to create the appearance of lath and plaster in older homes.

Soundproof drywall

The STC of soundproof drywall is increased by using laminated drywall manufactured from a combination of wood fibers, gypsum, and polymers (sound transmission class).

Because this drywall is denser than conventional drywall, it may be more difficult to cut than other types. It is employed in situations where noise is an issue or when silence is required in a room because of its soundproofing properties.

Fire-resistant drywall

In garages and basements, specialized fire-resistant drywall is applied around equipment that could spark a fire. It contains fiberglass, which slows fire spread and prevents it from burning as quickly as conventional gypsum. Type X and Type C drywall are the two varieties of fire-resistant drywall.

Type X is 5/8″ thick and provides up to one hour of fire protection. If necessary, it can be used in many layers to give additional protection. Type C is similar to Type X except that it does not shrink when burned. It’s mostly utilized in ceilings to keep them from collapsing in the event of a fire.

Foil-backed drywall

Foil-backed (yep, aluminum foil) drywall can be utilized to form a vapor barrier and improve the drywall’s insulating value when installed over wood, metal, and furred masonry. Because it absorbs and traps moisture, it should not be used as a substrate for tile or moisture-resistant wall coverings.

When using furred masonry, wood, or steel framework in new construction or remodeling, this type of drywall is suggested for use on the internal face of external walls and ceilings. However, based on what I’ve seen on online discussion boards, this new product is not well received.

Usage of drywall

The housing development boom that followed World War II propelled drywall into common use due to low labor and material prices. Compared to the old, time-consuming method of plastering wood walls, drywall is significantly faster, easier, and safer.

Because drywall is non-flammable, it is commonly utilized in commercial and residential construction to create rooms or partitions, particularly in condos and apartment complexes. Although all drywall is fire-resistant, type X and type C drywall are the most fire-resistant.

Some multi-family housing complexes advertise customized drywall with sound-dampening substances. If your upstairs neighbor has a late-night vacuuming habit, this is a cost-of-living bonus you’ll surely desire.

Drywall restoration is one of the most popular DIY tasks for homes since it is relatively simple, even if you have no prior installation knowledge. However, because drywall is delicate and easily damaged, it might be difficult for first-timers. However, the benefits outweigh the drawbacks; drywall is light and adaptable.

- Drywall projects aren’t just for the home anymore. In these situations, specialized drywall performs admirably.

- To keep bathrooms and mudrooms mold-free, drywall can be made water-resistant.

- In places like schools and hospitals, thick drywall is used for high-traffic walls and halls.

- The elevator and mechanical shafts are lined with drywall.

- Because of its flexibility, drywall is employed in custom designs because it allows for curved walls.

- To avoid radiation, builders install lead-lined drywall in medical and research facilities.

Advantages of drywall

Compared to traditional plaster, drywall has many advantages. It’s not that plasters are bad. But like every other industry, construction materials have also progressed a lot. As a result, some improved materials with greater benefits have been made.

If we look at the benefits of drywall, they are as follows:

- Installing drywall is faster and more efficient than plastering and uses less energy than any other approach.

- Although drywall installation is a labor-intensive task, the use of lifting devices saves a significant amount of time. Similarly, with the use of lifters/machines, ceiling panels can be fitted in no time.

- The drywall’s durability is inadequate, yet, the drywall’s strength is remarkable. The drywall also helps to keep the walls in place.

- The drywall becomes fireproof given the existence of calcium sulfate with water (CaSo4+H2O).

- It is inexpensive. When compared to plaster or other methods of leveling and smoothing the interior walls, it is less expensive.

- A drywall’s purpose might be both permanent and temporary. If drywall is put on the walls and ceiling, it will stay in place indefinitely. If drywall is used in place of a partition wall, it will only function as a temporary solution. It can be taken apart, sliced, changed, and adjusted as needed.

- Recessed lighting can be put into drywall walls or ceilings. Aside from illumination, any other equipment such as clothing hangers, mirrors, artworks, as well as other equivalent items can be readily placed on drywall.